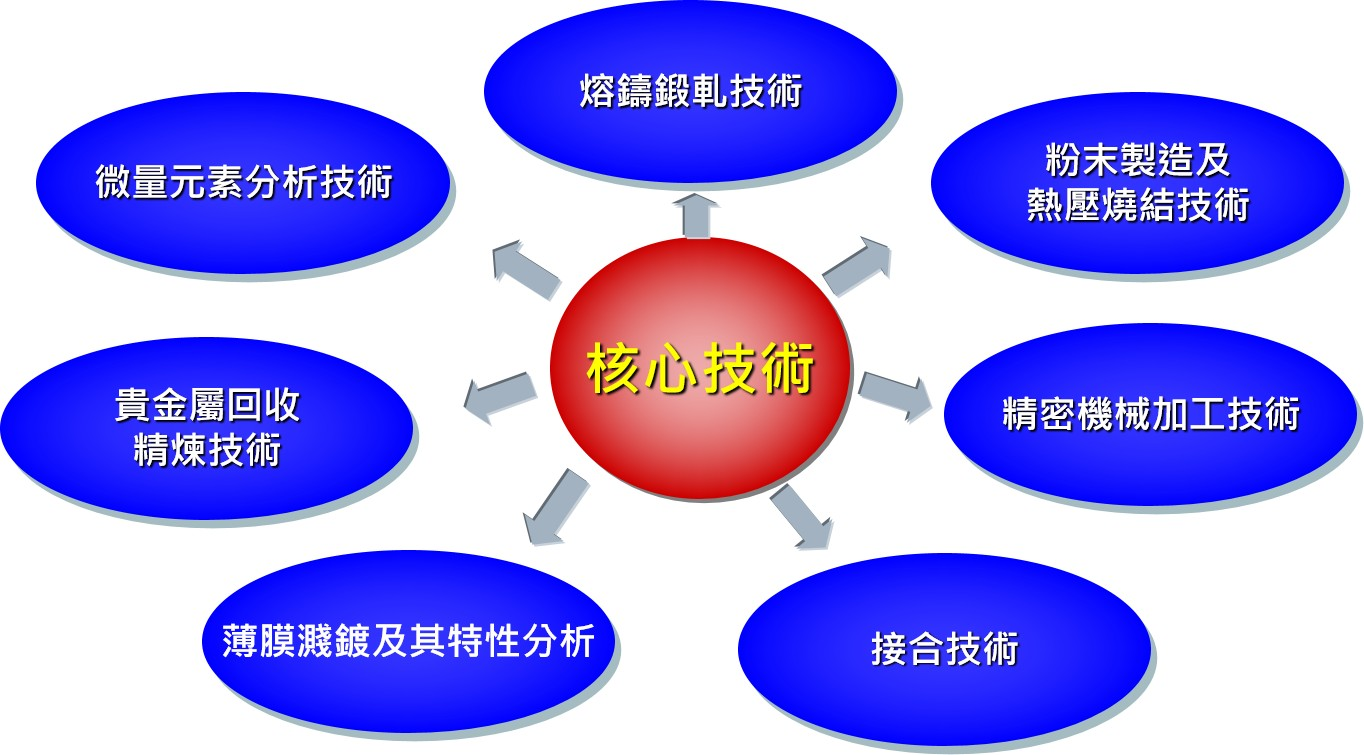

core technology

The company is committed to target development with many years of experience, has developed seven core technologies, such as casting forging, powder manufacturing and hot pressing sintering, precision machining, jointing, film splashing and its characteristics analysis, precious metal recovery and refining and trace element analysis, and has been continuously improving target characteristics control, such as material microstructure, grain size, texture and phase control.

R & D energy

The company has core technology of melting, casting, forging, rolling, powder metallurgy hot pressing sintering, etc. it can carry out special alloy proportion and process design according to different material properties and customer needs. In addition to continuously improving the target material processing capability, and developing new materials such as special alloy powder and silver powder, the company has successfully arranged new product fields such as 3D printing, metal injection, silver glue, etc.

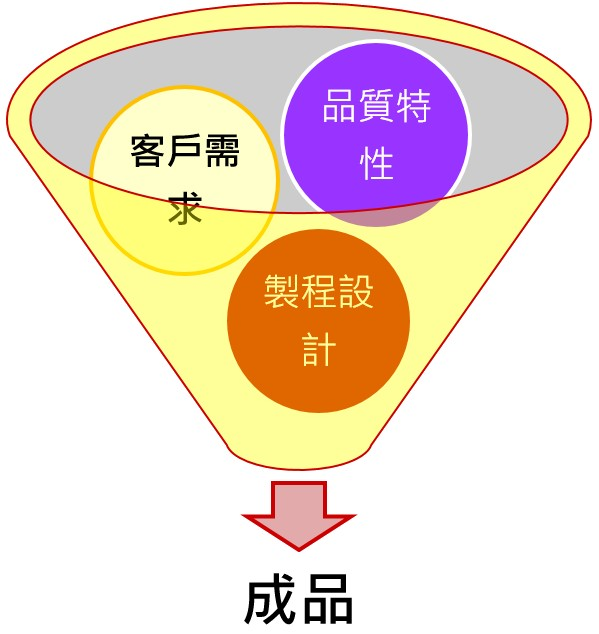

R & D process concept:

Process R & D equipment:

VIM, forging and rolling equipment.

VIGA, HP, hip.

Tube target and silver powder full process equipment.

The sputtering equipment includes RF, DC, DC pulse power supply, three target co sputtering and reactive sputtering.

competitive edge

With a strong R & D team, we can develop high cost-effective products with professional R & D and design capabilities, flexible to meet customer needs, and customized.

With melting, casting, forging, rolling, powder metallurgy hot pressing sintering and other full process equipment and technology, combined with full process control, stable product quality and delivery time.

Local service, closely cooperate with the delivery time required by customers, quickly respond to solve customer problems, and use professional technology and equipment to provide customer value-added services.

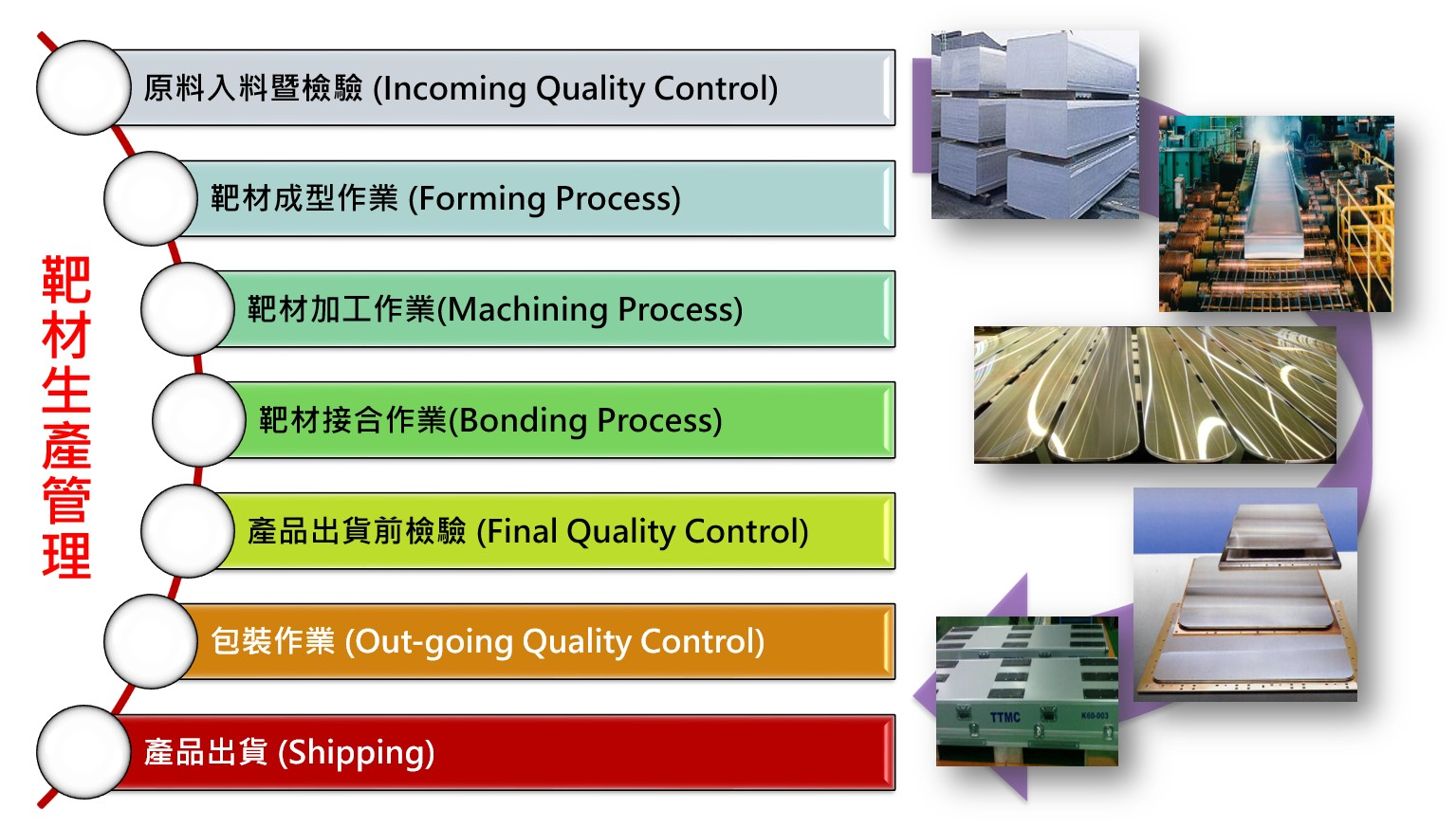

QA

The company's quality policy is "customer-oriented, pursuit of excellence, sustainable operation, continuous development of environmentally friendly energy-saving products without harmful substances.". The quality control procedures are based on the ISO 9001 and QC080000 systems, and are monitored from the whole process of feeding, manufacturing, finished product production and delivery to ensure that the product quality meets the customer's requirements, and the product quality is ensured through the quantitative data of various measuring and analysis instruments.

Quality control equipment:

In response to the demand of precision analysis, there are physical and chemical analysis laboratories. In terms of macro characteristic inspection, it has precise measuring instruments, such as three-dimensional measuring instrument, two-dimensional altimeter, hardness meter, coarseness meter, etc. Chemical composition analysis has high-order analytical instruments such as: inductively coupled plasma emission spectroscopy (ICP-OES), spark light-emitting instrument, nitrogen oxygen analyzer, ion chromatography, X-ray fluorescence analyzer (XRF), microwave digester, etc. Powder particle size analysis has bet, TGA and particle size analyzer. The microstructure and structure analysis include field emission electron microscope (FE-SEM), X-ray diffraction analyzer (XRD) and metallographic microscope.

Contact: manager Chen

Email: ivy@e-tcmc.com.cn

Tel: 0512-53303566-3005

Fax: 0512-53303066

Website: http://www.e-tcmc.cn/

Address: No.98 Ring Road, Industrial Development Zone, Shaxi Town, Taicang City, Jiangsu Province

|  |

Mobile phone station | WeChat public address |